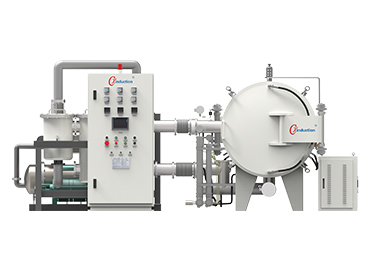

Polyimide Film Carbonization Furnace

Polyimide Film Carbonization Furnace

Product Introduction:

Complete the process of pyrolysis of organic matter to form inorganic cracked carbon. It is used to crack various phenolic resins to form hard carbon, polyimide cracks to form synthetic thermally conductive graphite, polyacrylonitrile fiber is carbonized to form carbon fiber, and polycarbosilane is carbonized to form silicon carbide ceramic fiber. The improved tar tail gas treatment device can complete the collection and harmless treatment of tar tail gas produced by most polymer cracking.

Applications:

The carbonization furnace is widely used in the pyrolysis of phenolic resin to make hard carbon, the pyrolysis of polyimide to make artificial thermal graphite film, the carbonization of polyacrylonitrile fiber to make carbon fiber, and the carbonization of polycarbosilane to make SiC ceramic fiber. The main purpose is to make inorganic Pyrolytic carbon by the pyrolysis of organic matter.

Synthetic graphite film carbonization furnace, specially designed to make vitreous carbon film by the pyrolysis of polyimide film in a vacuum and high temperature environment

Features:

Chamber Options:Single or Multi-chamber

Working Temperature: up to 1600°C

Heating Method: High-purity graphite resistance heat

Temperature Uniformity: ±15°C

Furnace type: Horizontal, Top loading,Bottom loading

Atmosphere: Vacuum

Specially designed tar filter device

Optional Features:

High Vacuum System

Gas Purification System

Closed Loop Cooling Water System

Distributed Control System (DCS)

Tail gas treatment system

Advantage:

According to different materials, the tar filtering device has been improved many times, so that the volatile content of the products in the furnace can be extracted to the outside of the furnace to the maximum extent, and the quality of the products is guaranteed while the charging amount per furnace is increased.

Categories

News

Contact Us

Contact: Amy

Phone: +8613873380233

Tel: +86 (731)-2863-2875

E-mail: cx381@chenxinzz.com

Add: No.473 Xiangneng Industrial Park,Hongqi Road,Zhuzhou,Hunan.